- Products

Fluorescence Spectrometer

Modular Raman Spectrometer

Finder 930 series Fully Automatic Raman Spectroscopy Analysis System Ultra-high performance scientific research CCD spectrograph High Performance Raman Spectrometer Confocal Raman System RTS-Mini Finder Insight Pro Raman Spectroscopy Handheld raman spectrometer Portable Raman Analyzer with Fiber Probe More>>Solar Cell System

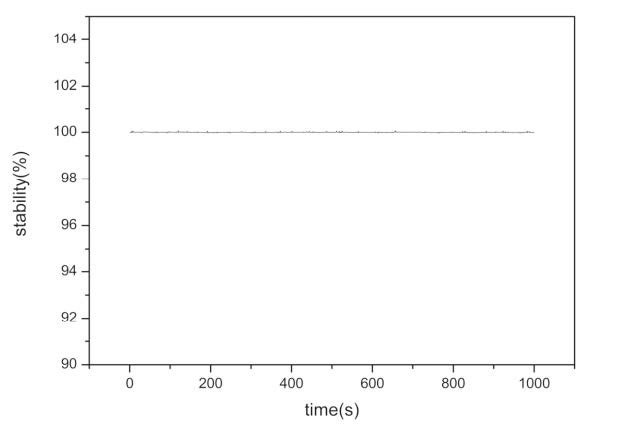

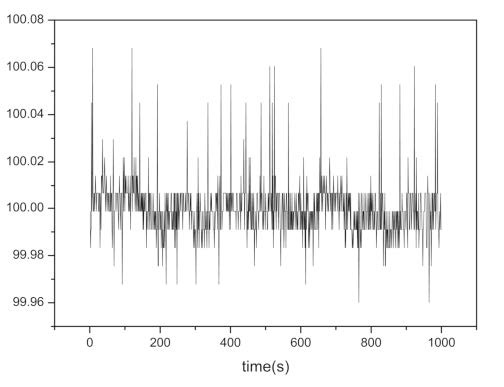

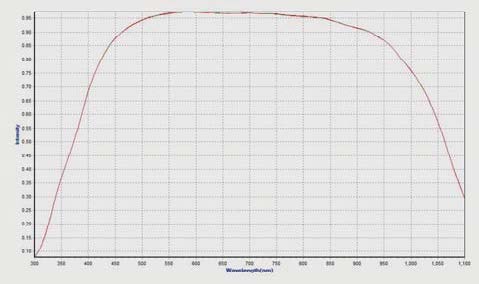

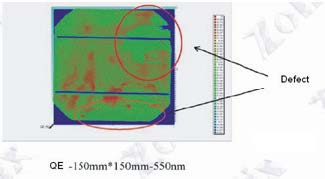

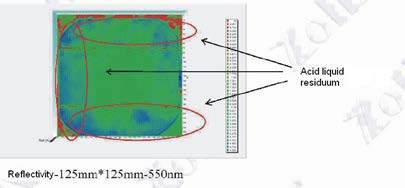

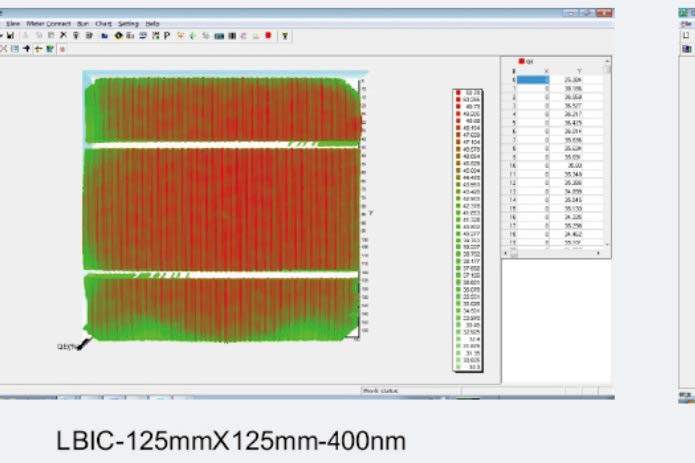

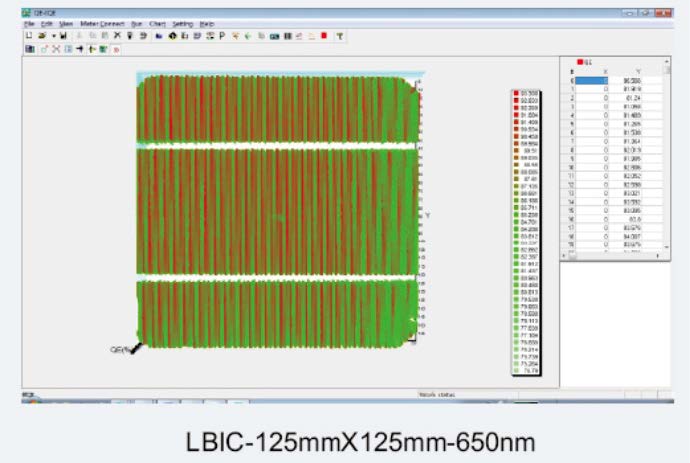

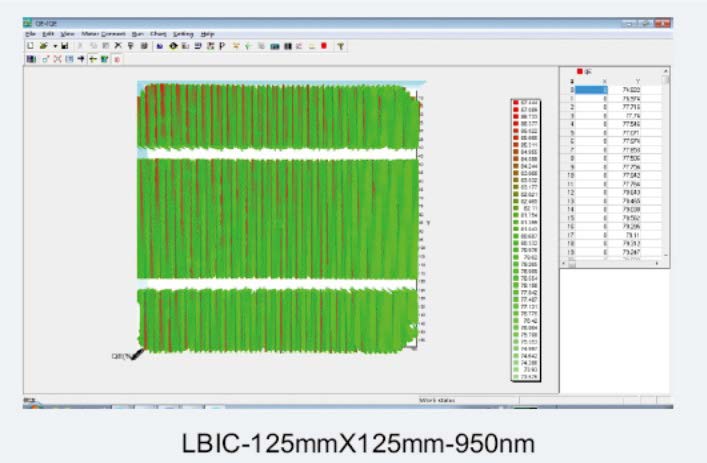

SolarIV series Solar Cell Voltage and Current(IV)Characteristics Test System Sirius series Solar Simulator QE-B1 Calibrated Monocrystalline Silicon Cell SCS600 Solar Cell Quantum Efficiency Measurement System SCS600-MAX Large Area Solar Measurement System DSR600 Photodetector Spectral Response Measurement System DSR300 Micro-nano Device Spectral Response Measurement System More>>Spectrograph & Monochromator

Motion Control

Motorized Linear Stages Motorized Vertical Stages Motorized Goniometer Stages Motion Controllers 2D- or 3D motorized alignment stages Multi-axis systems Piezo-Motion Units More >>Manual Positioners

- Applications

- Resources

- Services

- News

- Company

-

13910278534

13910278534

010-56370168

010-56370168